Tech papers

Asset Performance Management: Oil and Gas

POSTED 05/03/2023

| By: OnLogic

资产绩效管理ment (APM) in the oil and gas industry enables quick decision-making based on real-time data. APM helps keep downtime to a minimum and aids in minimizing the number of on-site workers required to keep operations running. But how do you create a solution that offers real-time insight into asset performance?

In this article, we’ll take you through a few of the key elements of APM in the oil and gas industry and how to leverage them to get the most out of your operations. For the latest tech updates and industry tips & tricks,be sure to subscribe.

What is asset performance management and why is it needed?

资产绩效管理ment combines data collection and analytics to improve the health, reliability, and output of physical assets. For oil and gas applications, having real-time insight into operations on structures like oil platforms and drilling rigs offers many benefits, all of which can drastically help to reduce the cost of operations. Some of the many ways asset performance management benefits the oil and gas industry include:

- Decreased unplanned downtime

- Better maintenance scheduling capabilities based on predictive and preventive analytics

- Increased lifespan of assets

- Better resource allocation

“连接边缘扩散计算开发ices is a game changer for the Oil and Gas industry. By leveraging Industrial IoT capabilities, organizations now have more tools than ever before (such as Remote Sensor Monitoring and AI enabled Computer Vision) to support a preventative approach of managing the performance of their critical assets.” – Ross Hamilton, Senior Hardware System & Solution Architect at OnLogic.

Foundations of an asset performance management system

For an effective APM system, both hardware and software are needed. Although there are many different hardware options to choose from, the dependable processing capabilities of industrialedge computersmake them an ideal choice for the gathering and real-time processing of data that APM requires. Unlike with cloud computing, which sends data to a central data center for processing, edge computing handles data right at the source, improving response time, mitigating security risks, and reducing data handling costs.

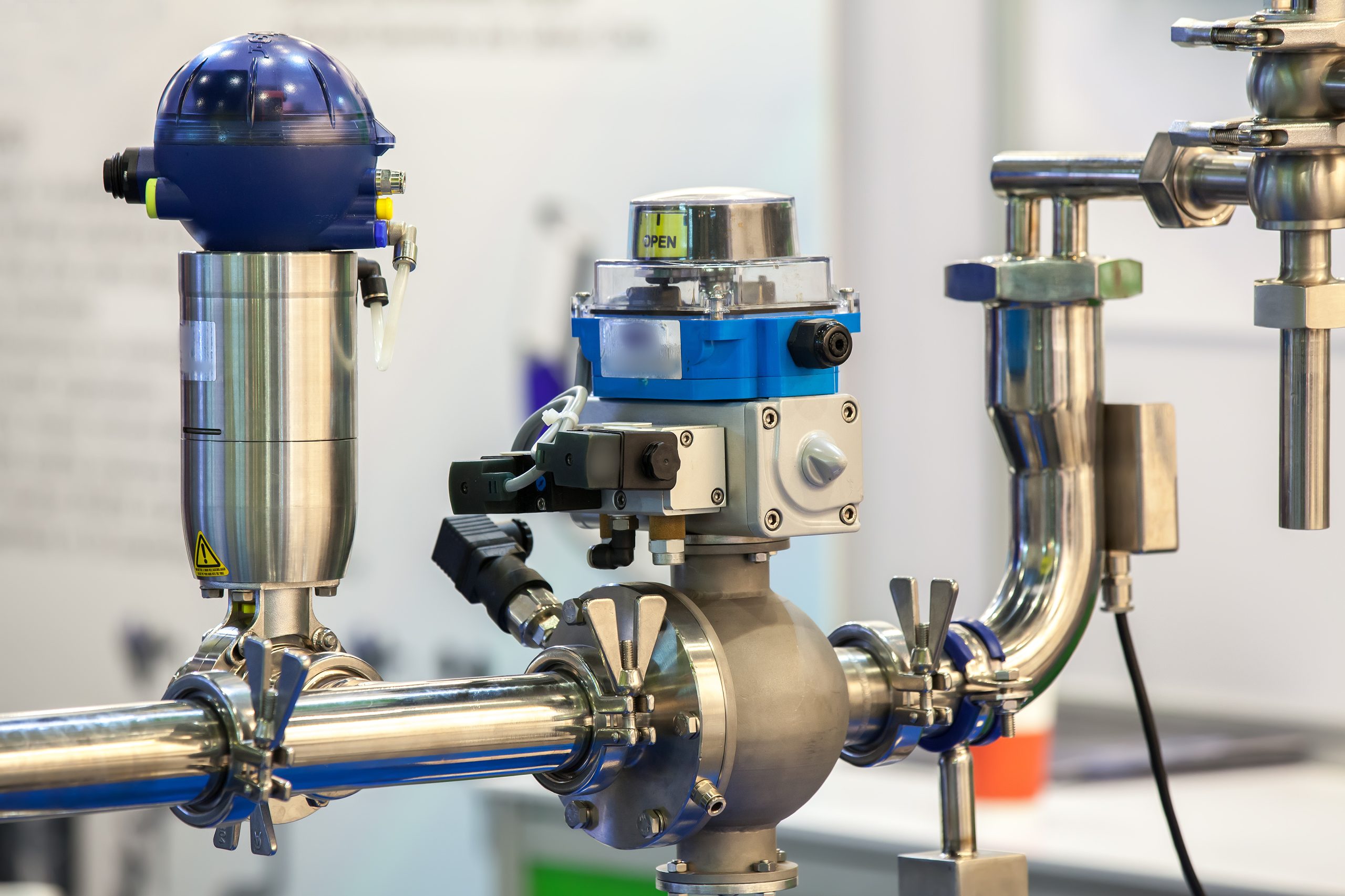

An edge computer can be connected to a variety of on-site sensors (cameras, audio, proximity, accelerometers, gyroscopes, magnetometers, etc.) as well as other types of data collection devices that can provide information back to a network connected infrastructure.

For example, let’s say you have an infrared camera set up for optical gas imaging (OGI) to monitor on-site pipes and detect abnormalities. Connecting this camera to an edge computer would allow you to monitor these pipes in real time and quickly be alerted to any problems, improving response time and helping to prevent downtime, costly damage, and potentially hazardous gas leaks.

Because oil and gas applications often feature challenging operating environments, traditional PCs can fail under the stress of the harsh conditions.Rugged computersfrom OnLogic are a good solution to this due to their wide operating temperature range and resistance to impact forces, vibration, dust, debris, and other airborne particulates. Systems like theKarbon 400andKarbon 800are ideal for asset performance management within these environments.

For situations where a rugged computer may not be needed, theFactor 201and theFactor 202can also be a great addition to an APM solution. You can also check out our blog onhow to choose the best PC for edge computing in the oil and gas industry.

OnLogic is here to help

Having the right hardware makes all the difference when deploying an asset performance management solution. At OnLogic, we have the durable hardware you need for your unique application, whether you’re on an oil platform in an ocean or at an offshore drilling rig in Alaska. If you have any questions about our systems or how they can be leveraged for asset performance management,contact our expert technical sales team today.