Stäubli Robotics Product

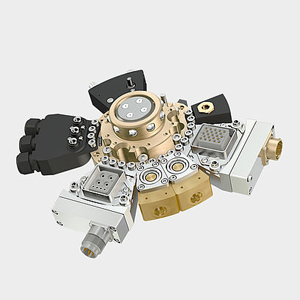

Robotic tool changing systems from the MPS product line are impressive due to their multifunctional technology applications and cover the entire bandwidth of customer-specific applications. The MPS 130 is an extremely flexible solution for medium payloads. This automatic, very compact tool changer offers numerous module variations for various components within media, data and energy transmission, such as pneumatics, vacuum and cooling, signal and power supply and primary current.

Applications: Gripping/handling, Resistance spot welding, Friction element welding, Laser welding, Clinching, Punch riveting, Screw FDS, Roller folding, Gluing, Vacuum and material transfer, and special applications on request.

Technical data: Payload up to 100 kg, Bending moment up to 900 Nm (static), Torsion moment up to 800 Nm (static), Locking: pneumatic (additional protection by compound spring on pressure drop), Operating air pressure: 0.45 MPa – 0.8 MPa, Flange fitting per EN ISO 9409-1-100-6-M8

Coupling modules for media, energy and data transmission: Electrical connector for data and electrical signal transmission, Primary circuit plug for welding current transfer, Media couplings for liquids and gases, Pneumatic and vacuum module, Security module for Active Docking Performance Level d, Category 3, Further modules on request

Docking station: Flexible and robust docking station, Deployable vertically or horizontally, Standardized or customer-specific docking stations, Can be integrated into the plant control system, Optional protective cover for harsh environments, Optional additional sensors

Programming jig: Easy installation of the programming jig by means of a click function, Quick and easy determination of the dome position, Exact positioning for fast and trouble-free docking operations as well as a long service life, No additional software required