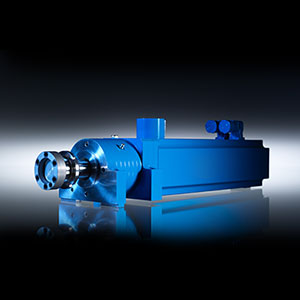

Kistler Group Product

Process Inspection: the Guarantee of Quality

The Benefits of Using INSPECT Systems

- Reduced quality costs

- In-process error detection

- Immediate in-process quality correction

- Optimized fasteners

- Enhanced efficiency in the fastening process

- Documentation

- Protection against product liability cases

- Reproducible inspection processes

- Traceable results

- Compliance with standards

To monitor the quality of production processes in fastening technology: that is the purpose of our vast range of high performance INSPECT systems for fasteners such as bolted joints. As well as monitoring the fastening processes, our systems ensure that errors are detected at an early stage so they can be rectified as quickly as possible. These products ensure that fastening processes are reliable. But that's not all: by playing a fundamental role in process optimization, they contribute to the continuous improvement process in production.

Convincing Advantages for Your Business

All our efforts to achieve optimum fastening processes through quality assurance focus on one goal: business success for our customers. There is only one way to boost productivity and enhance quality: by consistently increasing process reliability and optimizing the use of monitoring, so as to cut down outlay on inspections and corrective measures.

Compliance with Standards: a Key Quality Characteristic

Requirements for process inspections on fasteners are governed by a wide variety of international and customer-specific standards. These requirements change constantly to keep pace with the latest technological developments. That's why our inspection systems are highly flexible, with the ability to adapt repeatedly to the latest requirements. The software structure is designed for regular updates, and the modular structure of our INSPECT systems means that changes to hardware

需求可以实现ed immediately.

Click hereto learn more about Process Inspection by Kistler.