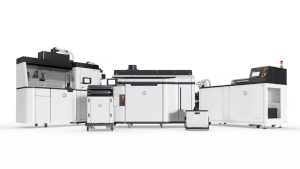

HP 3D Printing Product

Quality, functional parts

- Ideal for industrial prototyping and final part production.

- Achieve predictable print time and parts with best-in-class isotropy.

- Choose between print modes tuned for mechanical/functional/aesthetic properties, accuracy, and speed.

优化的连续ctivity

- Produce more parts per day with continuous printing.[1]

- Streamlined, cleaner experience with enclosed, automated mixing.[2]

- Rely on HP’s world-class HP Jet Fusion 3D Solution Services to maximize uptime and productivity.

Optimized costs

- Reduce operational costs, opening your doors to short-run production.

- Invest in a competitively priced 3D printing solution and produce at a low cost per part.

- Optimize cost and part quality, with cost-efficient materials that offer industry-leading reusability.[3]

l1] Continuous printing requires an additional HP Jet Fusion 3D build unit (standard printer configuration includes one HP Jet Fusion 3D build unit).

[2] Compared to manual print retrieval process used by other powder-based technologies. The term “cleaner” does not refer to anyindoor air quality requirements and/or consider related air quality regulations or testing that may be applicable.

[3] Industry-leading surplus powder reusability based on using HP 3D High Reusability PA 11 and PA 12 at recommended packing densities and compared to selective laser sintering (SLS) technology, offers excellent reusability without sacrificing mechanical performance. Tested according to ASTMD638, ASTM D256, ASTM D790, and ASTM D648 and using a 3D scanner. Testing monitored using statistical process controls.